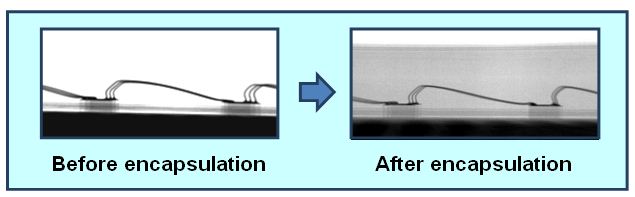

1)Enhanced reliability

Generally speaking, silicone-based encapsulation materials for LED are only available in a liquid

form. Building on its proprietary technologies, Nitto Denko succeeded in turning its liquid

thermosetting encapsulation resin into a gel-like sheet by utilizing a special silicone resin as a

base. The sheet does not cause any damage to LED bonding wires when laminated onto LED devices,

because of its gel-like, semi-hard property.

The sheet’s relatively small shrinking rate upon the completion of the thermosetting process also

contributes to enhanced reliability.

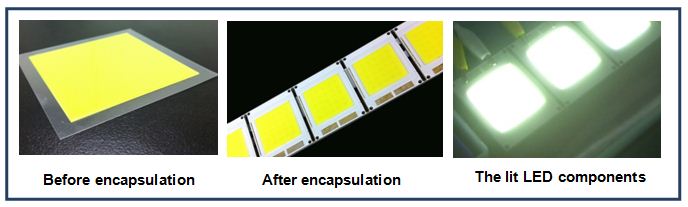

2)Enhanced productivity

The sheet made it possible to encapsulate a large area at once and the whole encapsulation process is

now greatly simplified because there is no need for setting up a “dam” to keep the liquid material in

place. Compared to the conventional “potting” method with liquid encapsulation materials adopted at

IDEC, the new sheet-encapsulation process requires only about one-ninth of the previously required

time for completion.

3)Improved color consistency

In the conventional method with liquid encapsulation materials, it took a certain period of time until

the liquid was completely set solid, so that the phosphor material inside the liquid sedimentate to

the bottom in the process and they caused variation of a finished LED’s color. With Nitto Denko’s new

encapsulation sheet, such concerns can be eliminated. In addition to lessened color variation by half

(compared to IDEC’s conventional method), the skipping of blending and mixing steps contributed to the

productivity enhancement.

4)Less-expensive initial investment

Thanks to the now simplified production process, only one-tenth of the initial capital investment is

needed compared to the conventional production line. (Internal trial calculation)